Industrial Hydrogen.

Engineered for Reliability.Deployment.

Cold plasma hydrogen systems designed for continuous operation, modular scale, and industrial integration.

Energy Reduction Potential

Relative to conventional electrolysis benchmarks

Hydrogen Production Cost at Scale

Achieving economic parity with fossil-fuel alternatives

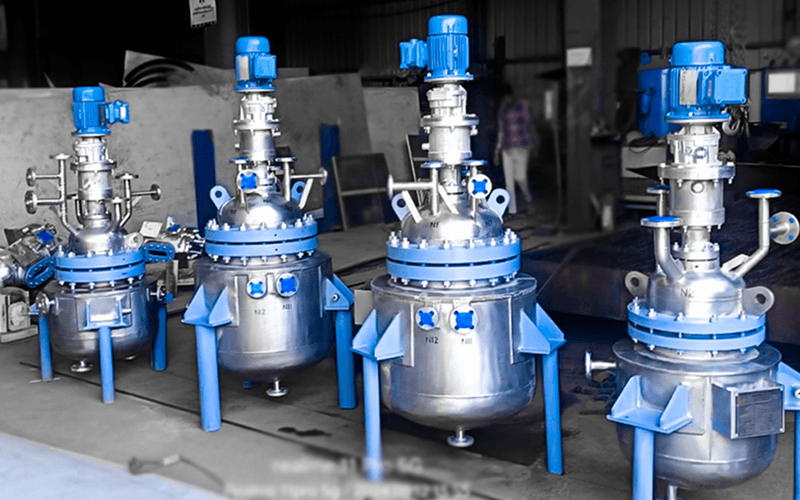

Modular Production Units

Scalable to 250–500+ kg/hr clusters

Proven Reliability

Verified Performance

Global Safety

Market Opportunities

Proven Reliability

Verified Performance

Global Safety

Market Opportunities

Trusted by industry leaders for mission-critical hydrogen deployment.

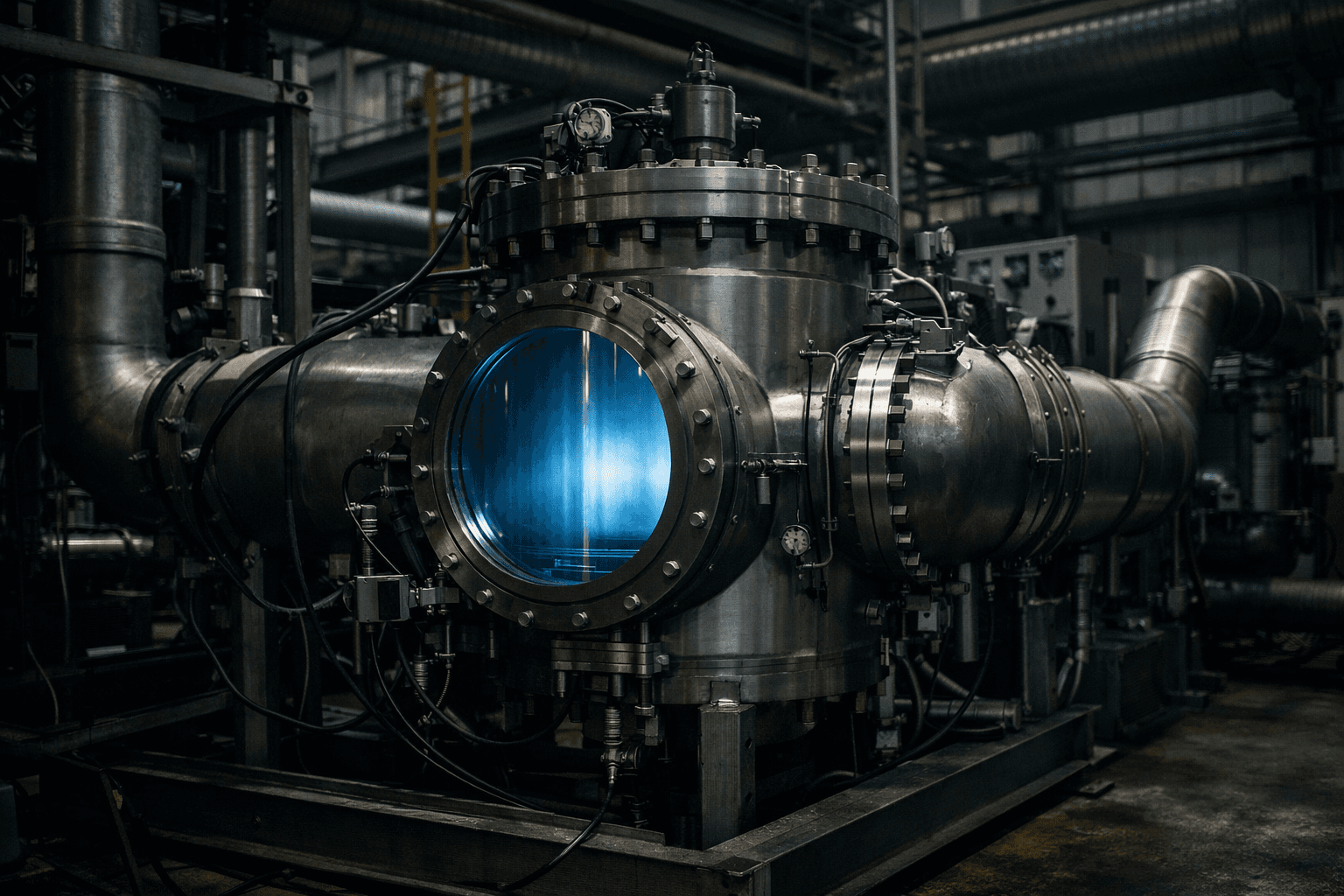

A Different Architecture for

Hydrogen Generation

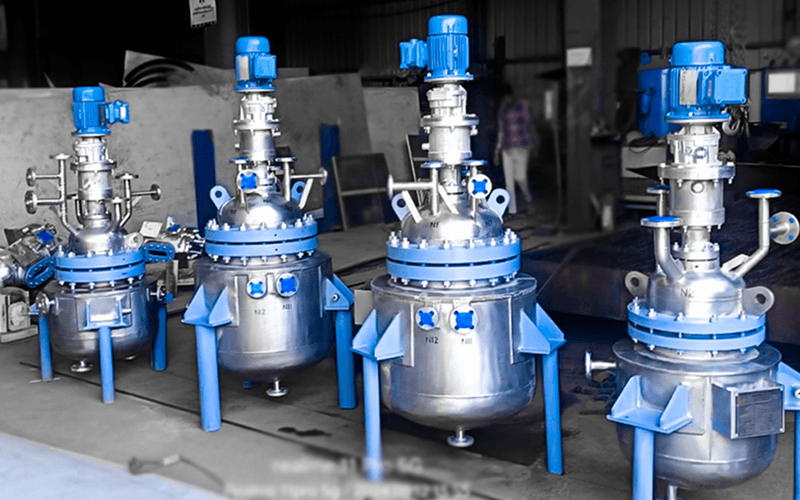

Gigacore’s platform uses controlled cold plasma excitation to activate water molecules under engineered electromagnetic conditions.

The system architecture:

- Modular reactor clusters

- Near-ambient operating conditions

- Industrial power electronics

- Integrated control systems

Industrial Reliability.

Engineered for Uptime.

Industrial systems require predictable performance. Gigacore’s architecture is engineered for reliability, redundancy, and scale—delivering consistent output in the harshest environments.

Systems designed for 24/7 industrial duty cycles without frequent stack degradation. Our proprietary thermal management ensures consistent output even under variable load conditions.

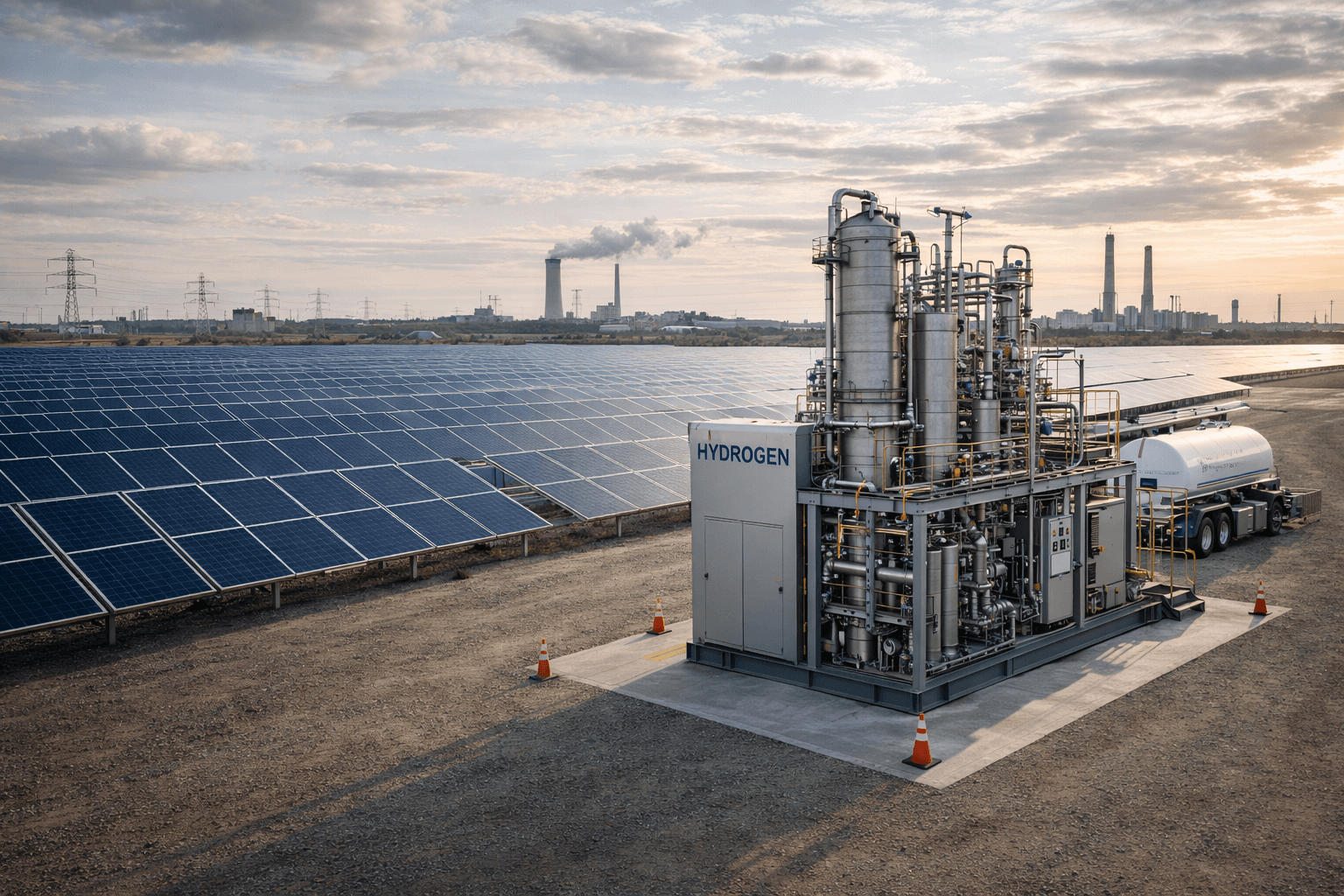

Deployment Pathways

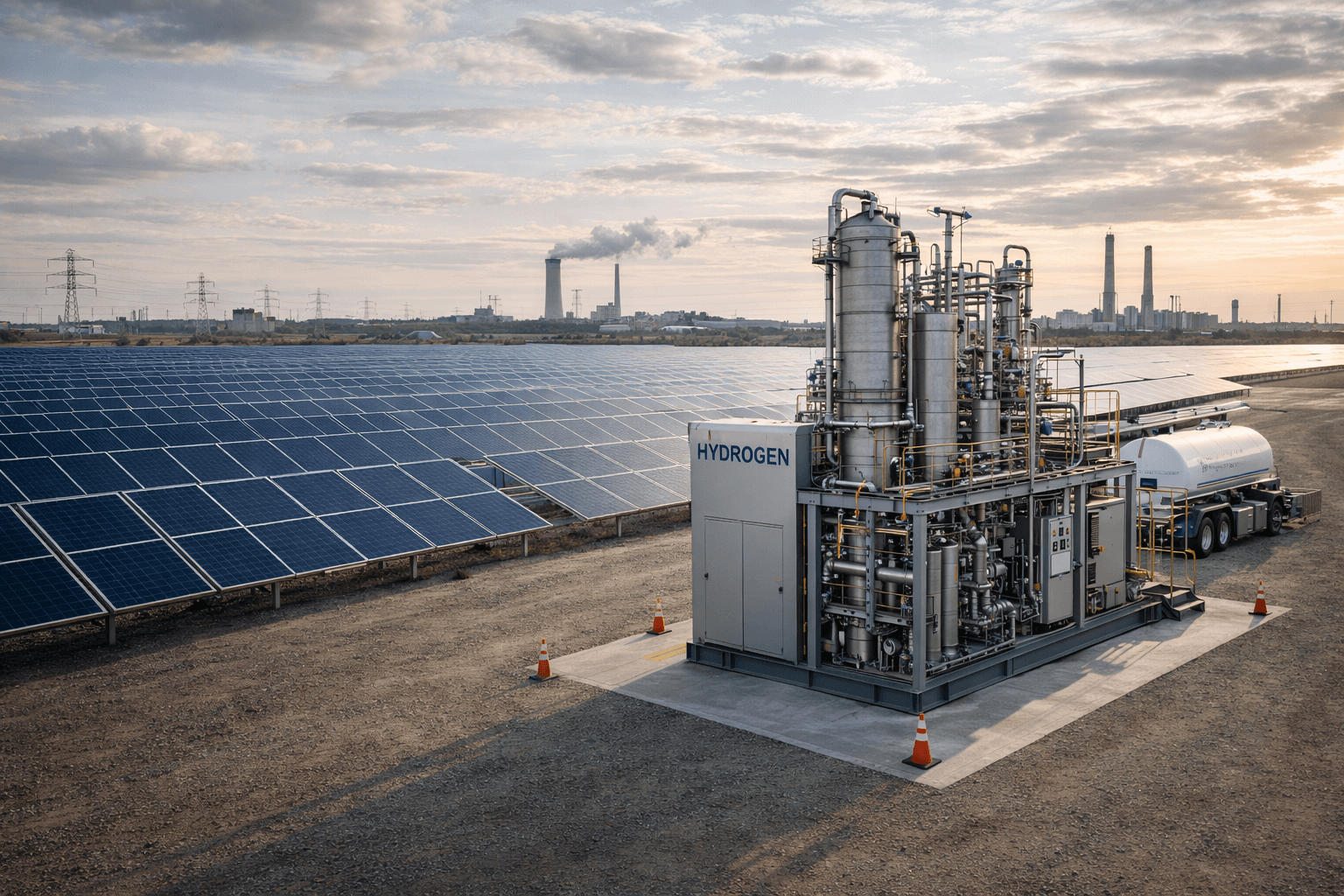

Gigacore systems are structured for massive-scale integration across critical industrial sectors.

Green Ammonia

Decarbonizing fertilizer production with scalable H2 feedstock.

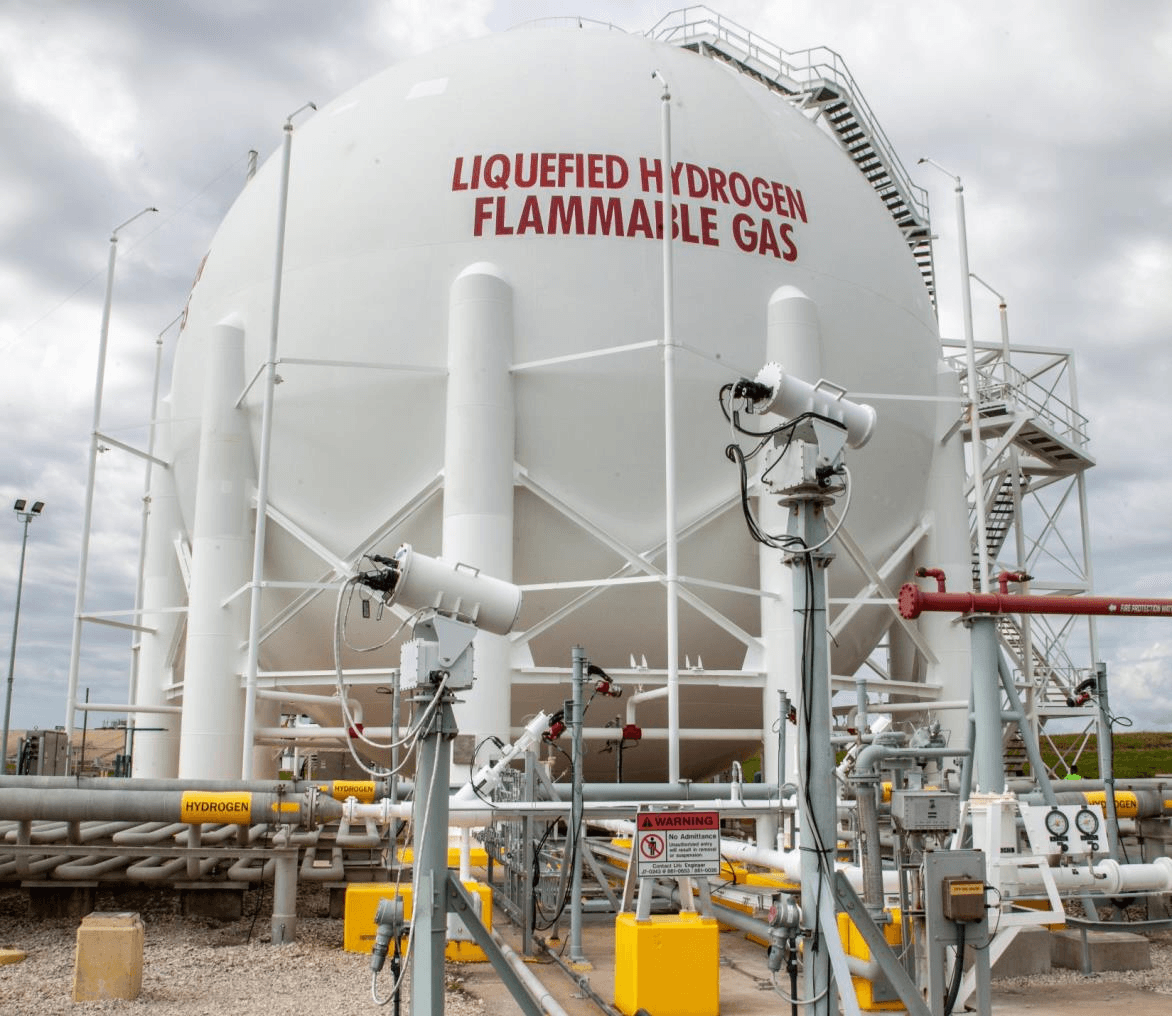

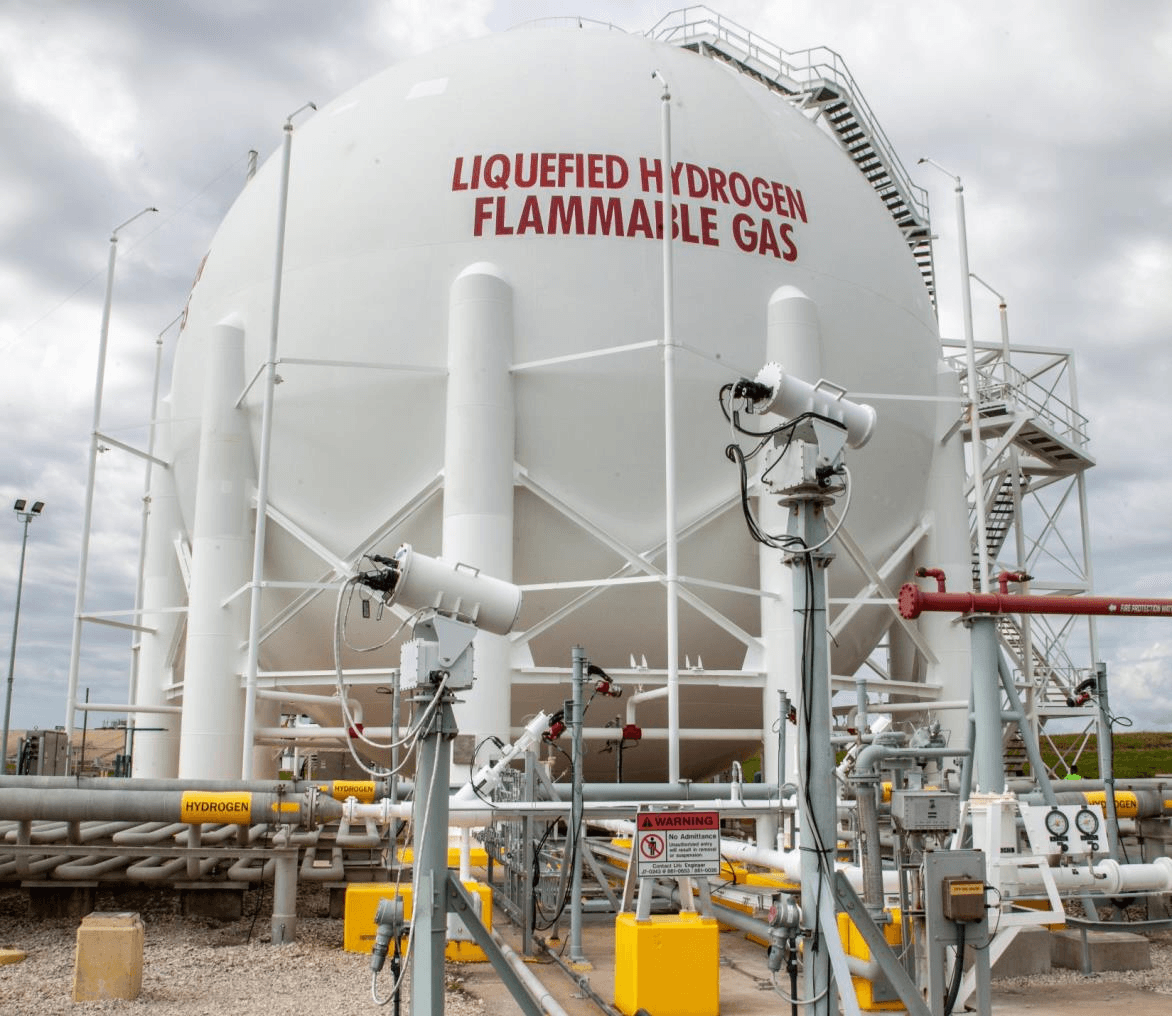

Industrial Supply

On-site generation replacing delivered bulk hydrogen logistics.

Hybrid Integration

Balancing renewable intermittency with baseload industrial demand.

Modular Scaling

Flexible capacity expansion for growing industrial needs.

Green Ammonia

Decarbonizing fertilizer production with scalable H2 feedstock.

Industrial Supply

On-site generation replacing delivered bulk hydrogen logistics.

Hybrid Integration

Balancing renewable intermittency with baseload industrial demand.

Modular Scaling

Flexible capacity expansion for growing industrial needs.

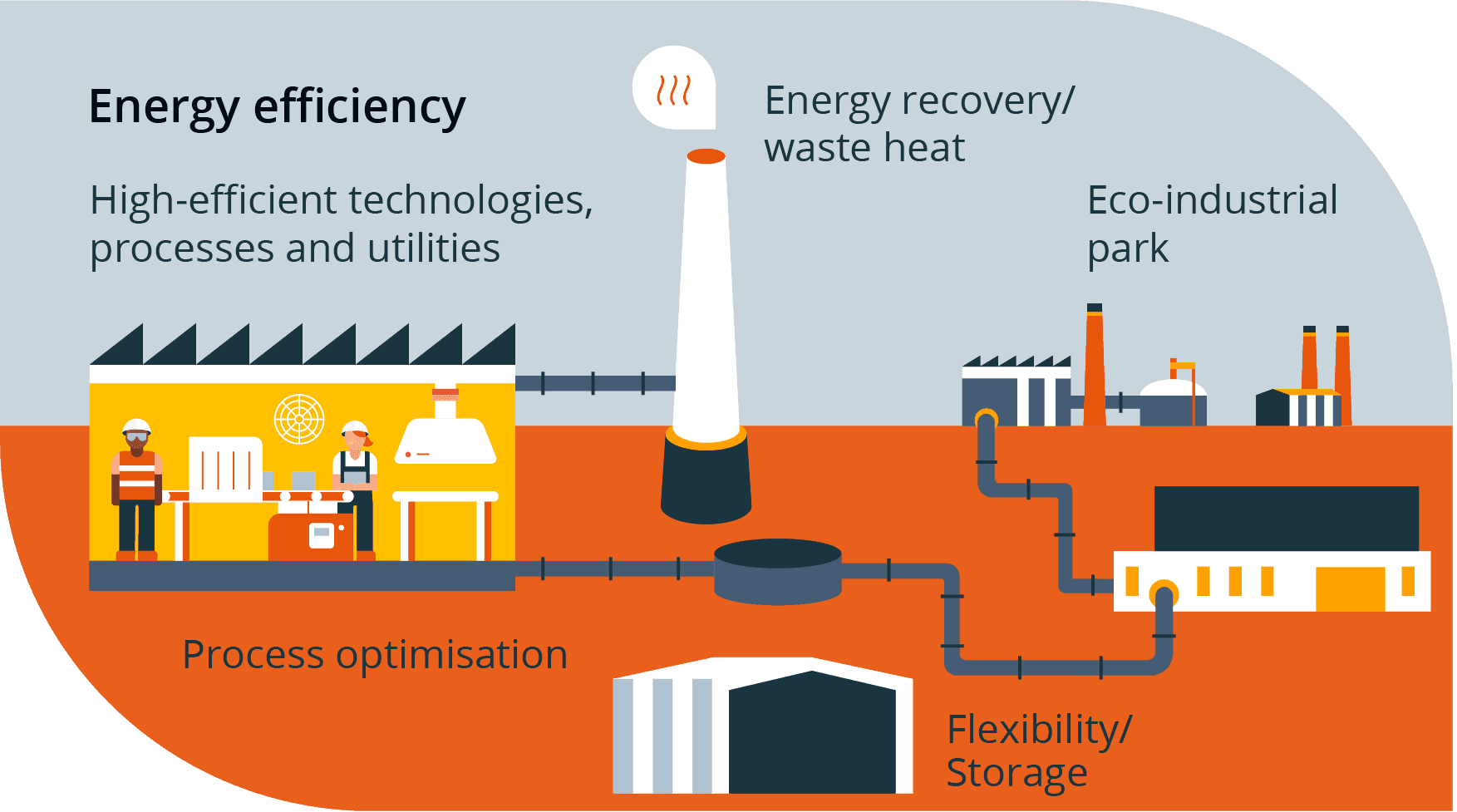

Designed Around

Energy Efficiency

Hydrogen economics are fundamentally driven by electrical input per unit of output. Gigacore’s architecture prioritizes ionization efficiency to minimize operational expenditure.

Optimized Energy Transfer

Direct modulation of plasma density matches input availability without significant rectification losses.

Elimination of Auxiliary Loads

Removal of high-pressure circulation loops reduces system-level parasitic energy consumption.

Linear Capital Deployment

Modular CAPEX scaling allows investment to strictly match actual demand growth.

Industry Collaboration

Gigacore works with industrial operators, engineering developers, and manufacturing partners to advance deployment readiness.

Pilot System Deployment

Validation of Gigacore stacks in representative industrial environments to confirm performance benchmarks.

Joint Integration Programs

Co-engineering of balance-of-plant systems for specific downstream applications in steel and chemical sectors.

Licensed Manufacturing Pathways

Enabling localized production for large-scale infrastructure projects through technology transfer agreements.

Insights Shaping

the Future of Power

Next-Generation Hydrogen Electrolysis at Industrial Scale

How advanced electrolysis architectures are reshaping the economics of green hydrogen for heavy industry, and what it means for the global energy transition.

Decarbonizing Heavy Industry: The Hydrogen Pathway

Heavy industry accounts for nearly 30% of global emissions. Exploring how hydrogen serves as a critical decarbonization vector for sectors that cannot easily electrify.

Green Hydrogen Economics: Reaching Cost Parity

An analysis of the cost trajectories for green hydrogen production and the technological breakthroughs needed to achieve parity with fossil-derived hydrogen.

Engage with Gigacore

For organizations evaluating industrial hydrogen systems, our team welcomes a structured technical discussion.